Lake Blue Glass Vase - Tranquil Waters Artisan Collection

Forged in fire and refined by hand, this glass is born from a transformative journey. Each piece is fired at over 1400°C, a temperature that purifies the crystal and prepares it to hold light with exceptional clarity. Through more than ten stages of meticulous manual grinding, carving, and polishing, artisans slowly reveal the glass’s inner life—sculpting forms that feel both fluid and precise.

True to the spirit of “one model, one product,” no two glasses are identical. The signature Flowing Clouds & Colorful design emerges naturally in the kiln, where mineral hues blend and swirl like captured sky at sunset. The result is a dazzling, ever‑changing play of color and motion—a small universe held gently in the hand.

This is more than drinkware; it is wearable light, a testament to fire, time, and the human hand. A piece that turns every pour into a moment of quiet wonder.

• Craft: High‑Fire Crystal (1400°C+) & Multi‑Stage Hand Finishing

• Character: One‑of‑a‑Kind Color Flow

• Includes:

1x Flowing Clouds & Colorful Art Glass

1x Fitted Display Box

1x Care Cloth

Product Specifications

Size S

Length 13.7 x width 12.6 x height 23.4cm

Diameter: 9cm

Weight:4.2kg

Size M

Length 12.6 x Width 12.6 x Height 30cm

Diameter: 8cm

Weight: 5.2kg

Specifications

Diameter:

Height:

Capacity:

weight:

Product Care

MAIN TAINING

HAND WASH

To prevent damage to items, it is recommended to clean them individually using warm water and non-abrasive cleaning products. We recommend setting your dishwasher on gentle mode or washing gently by hand.

DRY AND WIPE

Place the glass on a towel or absorbent kitchen paper and blot it dry, or wipe it carefully while holding the body with your thumbs to reduce pressure. Use lint-free fine cotton or linen towels. Put the cups back into the box or stand them upright without touching each other.

STORAGE and PRESERVATION

The edges of handmade crystal wine bottles are very thin, so they should be placed in a cupboard or packaging box with the cup mouth facing upward to prevent the cup mouths from touching each other. Do not stack wine bottles or hang them with hooks to avoid cracking the handles. Wine bottles should be stored in a clean and tidy place, with the mouth of the cup facing up and the cap open for ventilation.

MAINTENANCE

Do not leave wine in the bottle. Please clean it in time after use. The decanter must be cleaned with a soft sponge in warm water. Do not use detergent. If fog appears, pour some coarse salt and half a liter of alcohol. Shake vigorously and rinse with warm water several times. Insert absorbent kitchen paper into the cup for about 10 hours to absorb residual moisture.

The crystal glass material is purely hand-blown. Occasionally small bubbles and small scratches are normal phenomena. The crystal material is not resistant to high temperatures and cannot be heated and steamed. It is not suitable for boiling water to be poured directly into it. It is only suitable for daily tea temperatures below 50~60℃.

Optionen auswählen

Design

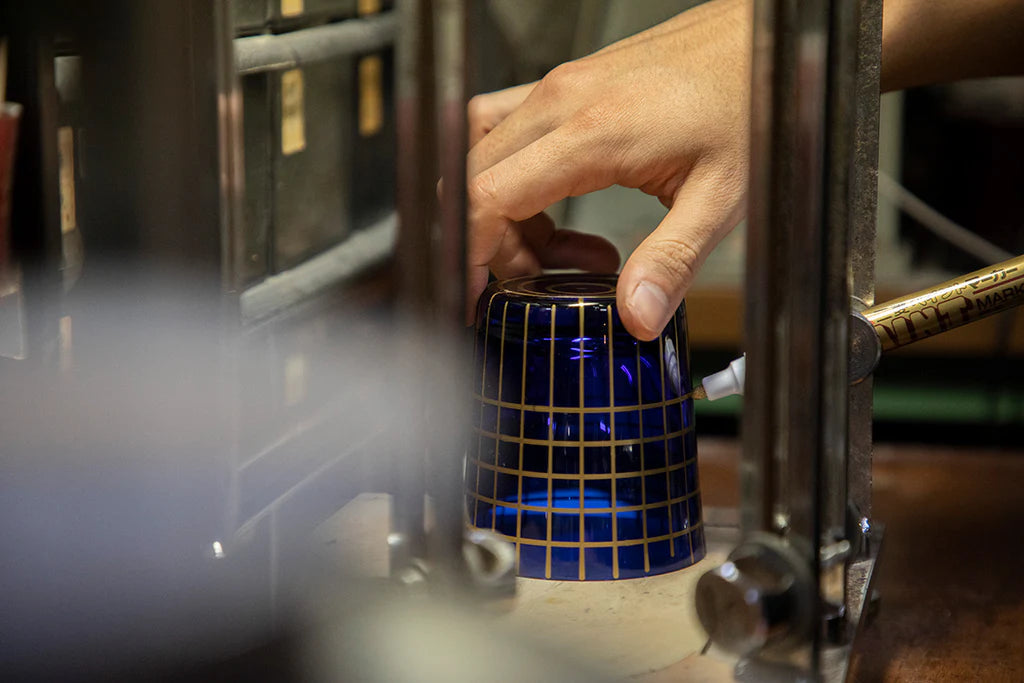

Crafting Of Edo Kiriko

The artist marks simple grid lines on the glass without drawing a design to provide the plan's framework. The design grid is drawn on the glass's surface using a bamboo stick or brush with red iron oxide. Next, the baselines of the design are lightly etched using a whetstone. Relying on these fine marks and lines, the delicate patterns of Edo kiriko are created with the artisan's expertise and skills.

First Cut

The base design is cut to about three-quarters of the final width and depth. The surface of the glass is cut using a sand paste-coated metal disc rotating at high speed. Generally, emery powder with many abrasive particles is used to create the sand paste. The clear pattern border lines and the irregular patterns are cut little by little. The balance between the thickness and depth of the cut lines relies upon the artisan's years of experience, as there are no detailed sketches.

Adjustments

The patterns cut in the second stage are adjusted, and the surface is smoothly polished in this process. A whetstone disc, natural or artificial, is used to cut delicate patterns which cannot be created with the metal disc used in the prior process. This is the last cutting stage to complete the designs, so careful work is required not to leave any powder residue and to ensure a brilliant finish.

Polishing

This is the final stage of production, and it is usually carried out on soda-lime glass (most prevalent type of glass). The opaque surface left by the third stage is returned once more to its original transparent state, with the attractive shine and sparkle typical of Edo kiriko. Chemical processing with hydrofluoric acid is also applied for high-class crystal glass. Depending on the piece, a variety of different polishing discs are used, such as paulownia wood discs, willow wood discs, hair brush discs, and belt discs. The final work is polished by applying water and polishing powders to obtain a glittering finish, while fine sections are polished with a cloth or a brush. To complete the final polishing, a cloth buffing disc is used to bring out the sparkle and shine of the cut glass.